Revolution in iMachining : SOLIDCAM

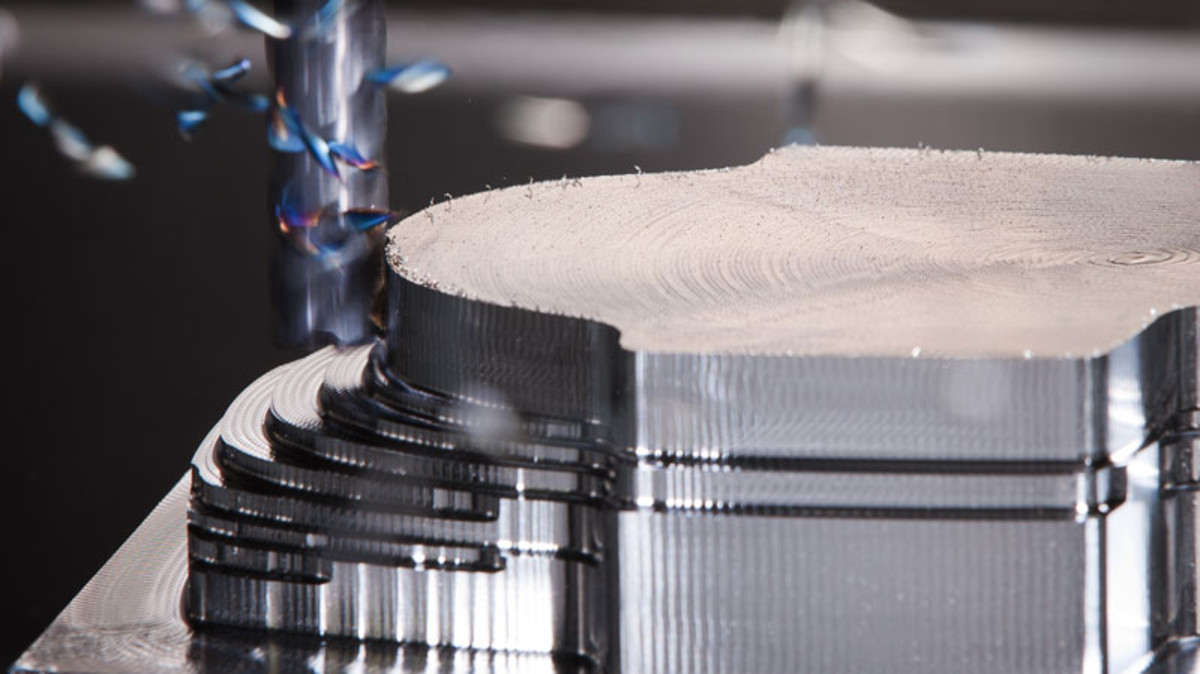

SolidCAM’s iMachining is a real breakthrough in CNC milling tool path technology that enables extremely faster and deeper machining by optimizing tool cutting angles and feed rates throughout the tool path. Use your existing CNC machines to run faster and deeper, even with the smallest cutting tools in the hardest materials.

- Saves 70% and more in CNC machining time

- Extends tool life drastically

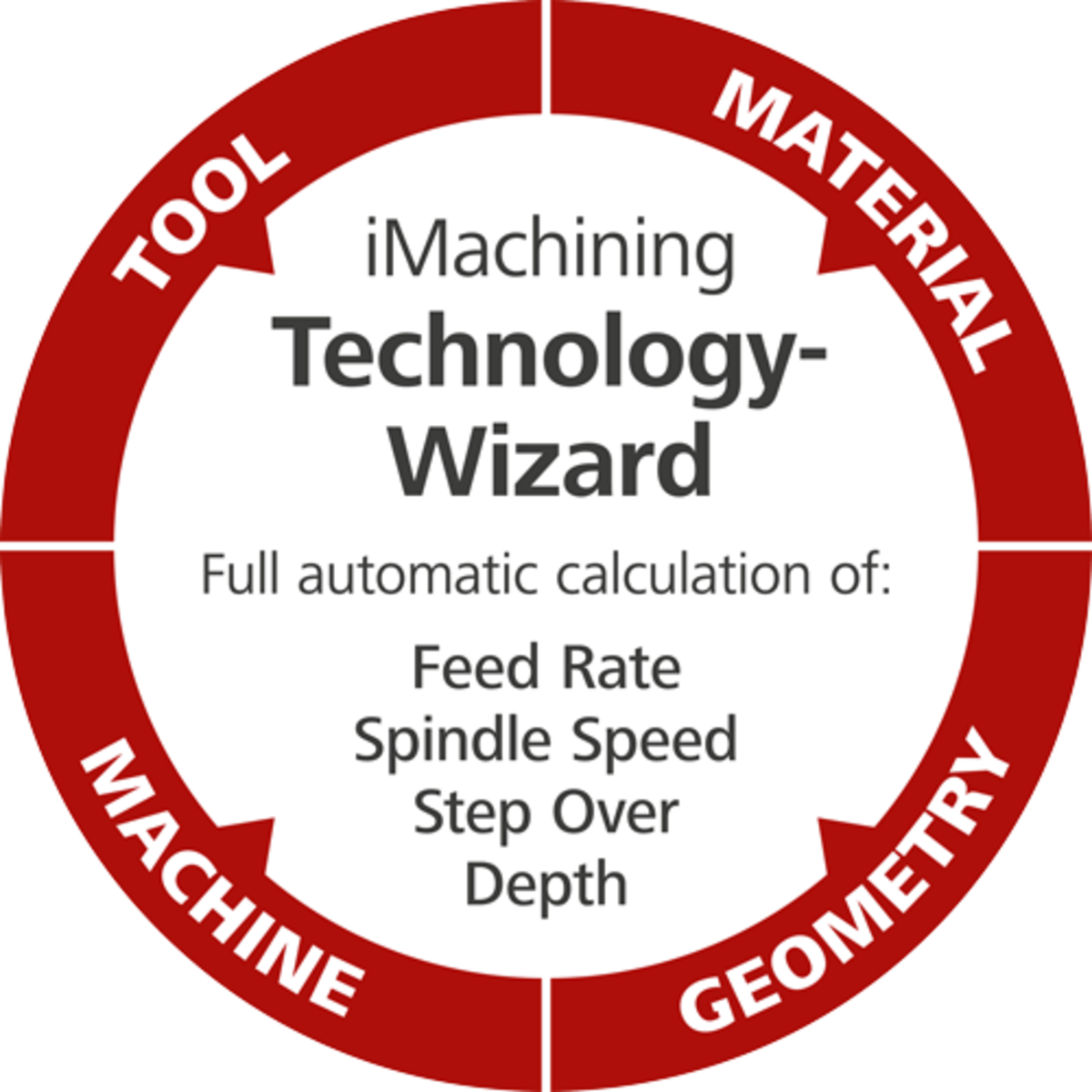

- Uses its patented Technology Wizard to provide optimal feeds & speeds based on tool path, stock material, type of cutting tool and CNC machine specifications

Benefits Of Choosing SolidCAM

Boost Your Profits by Greatly Increasing Your Machine Output with Extremely Enhanced Material Removal Rates:

- Machine deeper for far fewer passes

- Fully optimized Feeds & Speeds keep the cutter at maximum efficiency

- Rest-material (Exact Stock Material Machining) and finish cuts eliminate air cutting and unnecessary tool retracts to ensure you’re cutting ONLY what’s left

- Avoid machine downtime – less wear and tear on your CNC machines results in higher machine up time, reduced machine maintenance costs and extended machine life

- Skip costly machine tool upgrades and new CNC purchases – many planned purchases of new machines have been cancelled by happy iMachining owners

Slash Your Tooling Costs:

- Average Tool life increased by 5 times or more

- Full depth-of-cut ensures that the entire tool is utilized rather than only the bottom part

- Eliminate the cost of premium and specialty tooling for hard materials

Reduce Your Machining Time with the Unique Technology Wizard:

Reduce Your Machining Time with the Unique Technology Wizard:

- Automatic, optimal Feeds & Speeds eliminate the time-consuming trial and error to find the optimal machine settings – First-part success guaranteed.

- The perfect tool for even the most seasoned machinist for getting it perfectly dialed in, the first time – or for the less experienced machinist, iMachining will turn them into an expert in no time.

Categorised in: Tech